VR/AR/MR headsets and their optical components are rapidly progressing in their design and performance requirements.

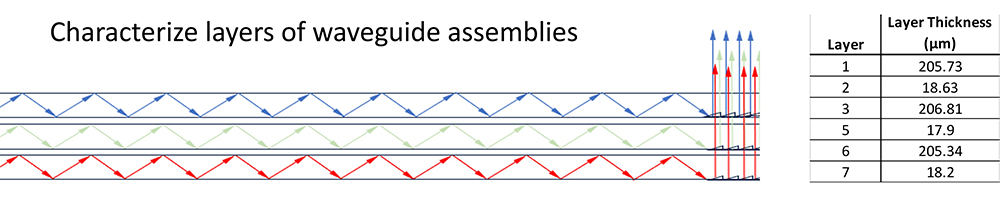

Bristol Instrument’s Optical Thickness Gauges provide non-contact, high accuracy material thickness measurements critical for the manufacture and inspection of VR/AR/MR optical components including complex lenses, waveguides and optical assemblies.

- Simultaneously measures all elements and air gaps of assembled components

- Non-contact measurement technique will not scratch or deform even the softest materials or coatings

- PASS/FAIL Quality Control software simplifies monitoring during the production process

- Straightforward operation provides consistent results across all operators

Straightforward Operation

This video demonstrates how quickly and easily lens doublets can be

measured to determine if they are within a specified tolerance.

Contact us to schedule a FREE analysis of your part.

Send us your part and we will provide a live video demonstration of our measurement capabilities.