How It Works

The Thickness Gauge systems from Bristol Instruments take advantage of the unique properties of light to accurately measure the thickness of transparent and semi-transparent materials. To make a measurement, light is directed onto the material under test resulting in reflections from each surface and layer interface. These reflections are collected and returned to the Thickness Gauge for analysis by an optical interferometer. The optical interferometer is basically a very precise “ruler” that can be used to determine the optical distances traveled by each reflection. The differences in these distances provide the information about the exact thickness of all the material layers.

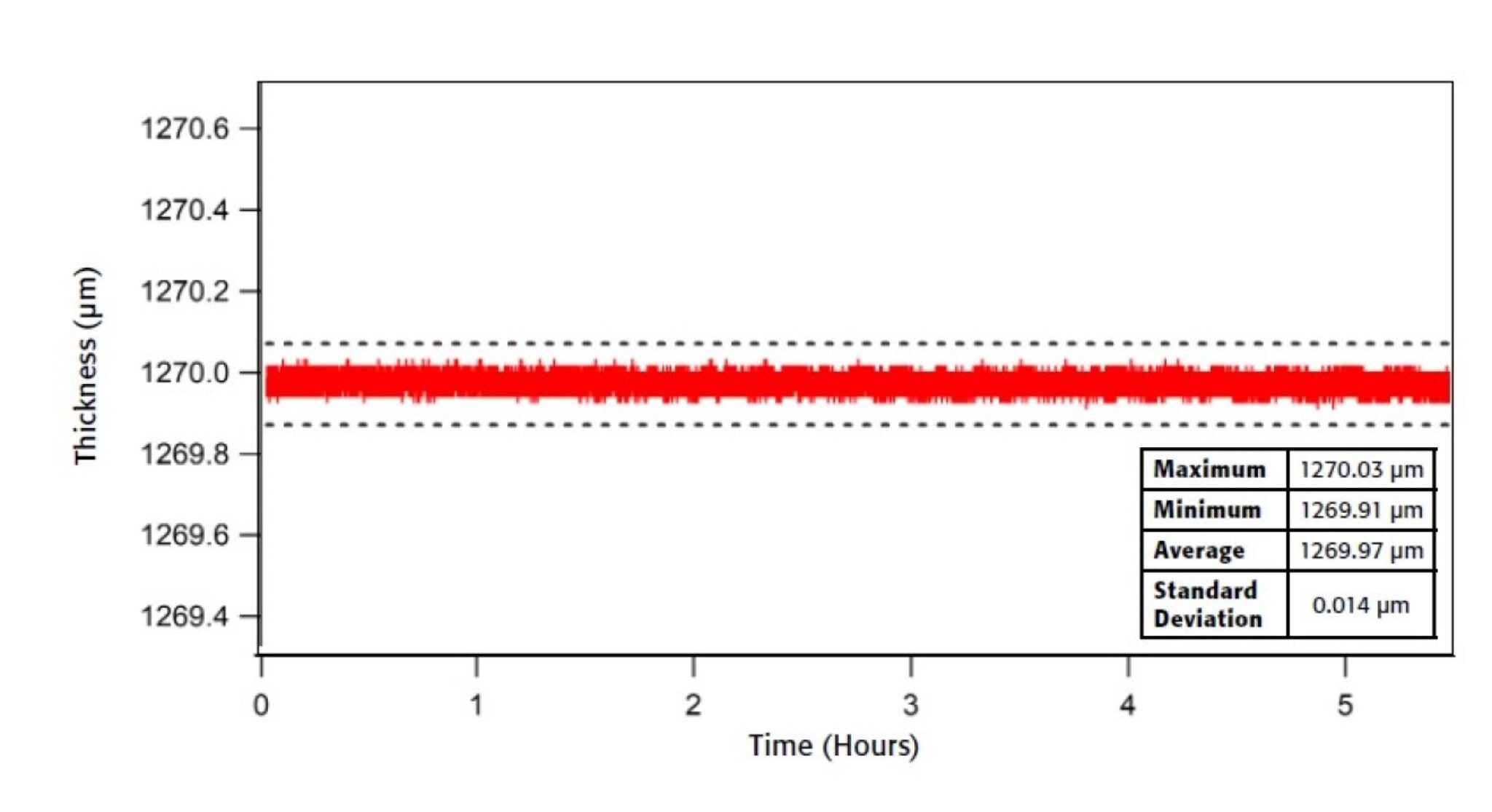

Reliable Accuracy and Exceptional Repeatability

The Thickness Gauge systems from Bristol Instruments offer the highest performance available to ensure the most meaningful test results. Thickness is measured to an accuracy as high as ± 0.1 μm with a long-term repeatability / standard deviation as small as 0.02 μm. Continuous calibration with a built-in standard of length and a unique interferometer design guarantees that this measurement performance is maintained year after year.

The Measurement Process

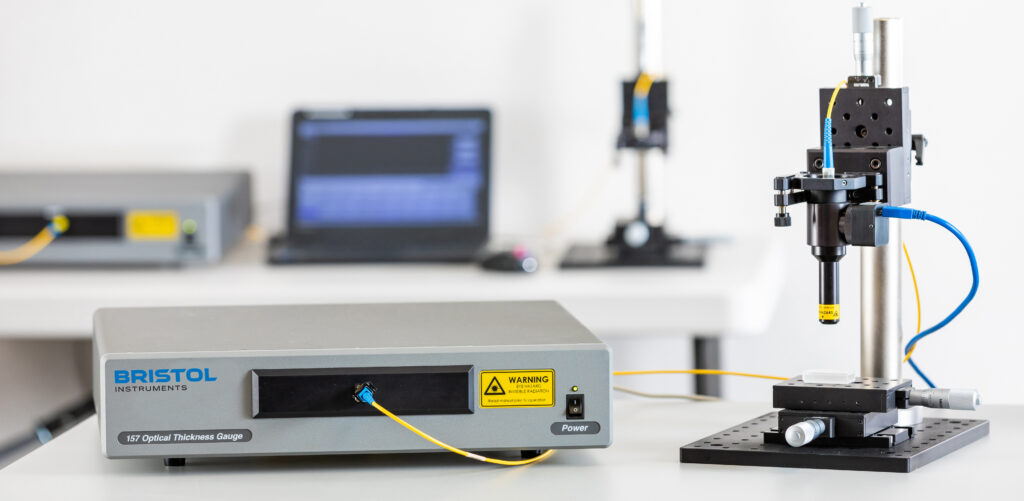

- The Thickness Gauge system includes a super-luminescent LED (SLED), optical interferometer, and a digital signal processor (DSP) housed within a rugged, rack-mountable chassis.

- Light from the SLED is directed onto the surface of the material under test through an optical probe that is connected to the Thickness Gauge system by a flexible fiber-optic patch cord.

- The optical probe is aligned to the material under test using common commercially available positioning components.

- Reflections from the material under test are collected by the optical probe and returned to the Thickness Gauge system’s optical interferometer for analysis.

- Thickness data is calculated by the Thickness Gauge system’s DSP and transferred to a PC using USB or Ethernet interface.

- The Thickness Gauge system’s Windows-based Opti-Cal software is used to control measurement parameters, display the optical signal for alignment purposes, and report thickness data in a variety of formats.

Contact us to schedule a FREE analysis of your part.

Send us your part and we will provide a live video demonstration of our measurement capabilities.